Advanced manufacturing

Showing the way to a greener and smarter future

- Industries

- Advanced manufacturing

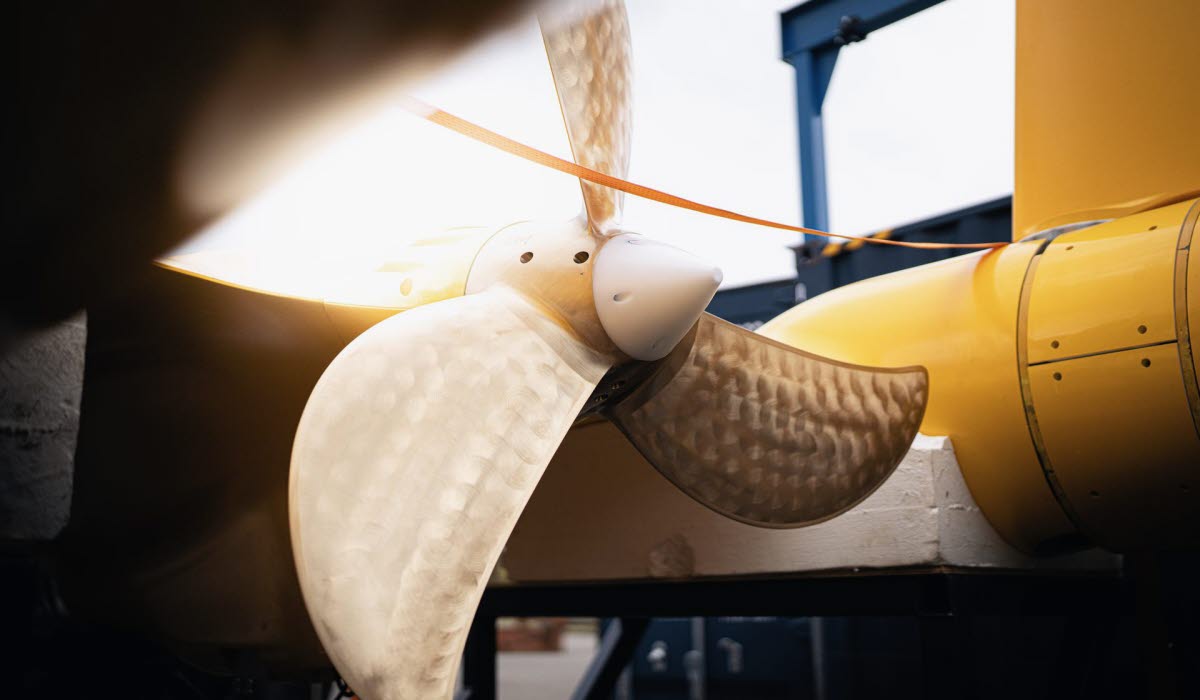

The smart industry is revolutionising how products are manufactured, distributed, reused, and recycled. Through innovations in 3D printing, automation, and data analytics—backed by world-class expertise—industries are setting the benchmark for the green transition.

Sweden is at the forefront of smart industry development with advanced technologies such as green battery production, wind power, solar energy, and hydrogen technology.

Key Points in Swedish Industry:

- Innovation and Collaboration: We build global alliances to accelerate the transition towards climate-neutral energy.

- Sustainable Production: We leverage technology and circular economy principles to minimise waste and optimise usage.

- Industrial Technology: Our expertise in system integration and digital solutions positions Sweden as a leader in Industry 4.0, from IoT to AI.

Business Sweden brings together multinational companies, start-ups, and industry organisations to push the boundaries in the industrial sector.

Are you ready to embark on the journey towards a connected, low-carbon future?

Contact our team

Advanced manufacturing Overview 2025

Sweden’s advanced manufacturing sector is powered by collaboration, sustainability and digital innovation, revolutionising how products are manufactured, distributed, reused, and recycled.

Download report